| Certified Standards of Thai Cosmos | ISO22000, HACCP, GMP |

|---|

|

|

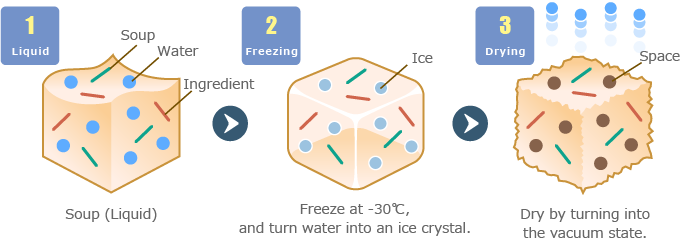

Vacuum freezing drier, Hot air drier, Freezing equipment, Crusher, Sorting line |

| Packaging equipment : | Pillow packaging machine, Various set up lines |

| In-Process Inspection : | Metal detector, X-ray inspection |

| Inspection/Analysis : |

Microorganism inspection, Water inspection, Pesticide residue inspection, Allergy inspection Others (Foreign substance identification inspection, Soil analysis, Nutrition analysis etc.) ※Inspect at an external inspection institute depending on an inspection item |